People must read materials and materials, and understand the carbon fiber giants abroad.-Tofore Carbon Fiber with Hanyan Indstrial

People must read materials and materials, and understand the carbon fiber giants abroad.

Carbon fiber has excellent mechanical, chemical, electrical and other properties, is an indispensable strategic new material for national economy and national defense construction, known as "black gold". In the 21st century, carbon fiber production technology has matured. With the continuous development of carbon fiber composite molding technology, downstream applications continue to expand, especially the strong growth of aerospace, automotive, wind turbine blades and their driving role, the development prospect of carbon fiber industry is broad.

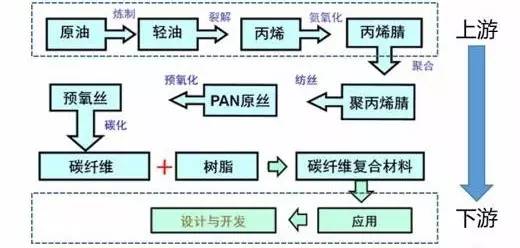

Carbon fiber industry chain

Carbon fiber industry chain can be roughly divided into the upstream production of carbon fiber materials and the downstream production of carbon fiber application components products, between the upstream and downstream enterprises can be considered as carbon fiber production process equipment providers.

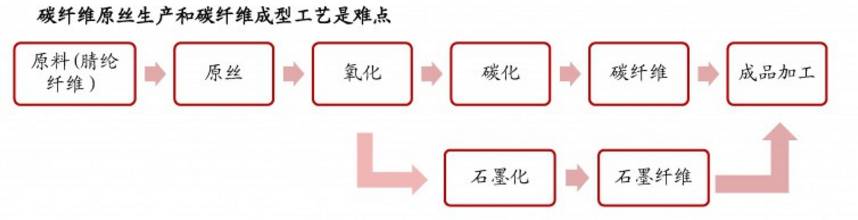

Composition of carbon fiber industry chain

According to our classification, the upstream of the carbon fiber industry chain includes the process from the precursor to the carbon fiber, that is, the precursor through oxidation furnace, carbonization furnace, graphitization furnace, surface treatment, sizing and other processes, the precursor with polyacrylonitrile structure will be carbonized into carbon fiber with graphite fiber structure as the main structure.

The upstream of carbon fiber industry chain is the petrochemical industry, mainly through crude oil refining, cracking, ammonia oxidation and other processes to obtain acrylonitrile; carbon fiber enterprises through the polymerization of acrylonitrile-based raw materials to produce polyacrylonitrile, and then spinning to obtain polyacrylonitrile precursor, the precursor for pre-oxidation, carbonization and other processes. Carbon fibers are prepared by processing carbon fibers and high quality resins to obtain carbon fiber composites to meet the application needs.

The production process of carbon fiber mainly includes drawing, drawing, stabilization, carbonization and graphitization.

Drawing: This is the first step in the production of carbon fibers. This process is a physical change, mainly the separation of raw materials into fibers. In this process, the mass transfer, heat transfer and phase equilibrium between the spinning fluid and the solidified fluid move. A filament that causes PAN to precipitate and form a gel structure.

Drawing: usually at 100-300 degrees of temperature, according to the tensile effect of knot-oriented fiber to achieve, this process is also to achieve high modulus of PAN fiber, high strength, densification and refinement of the key steps.

Stability: also known as pre softening. Thermoplastic PAN linear macromolecular chains were transformed into non-plastic and heat-resistant trapezoidal structures by heating and oxidizing at 400 C, which made them non-melting and non-flammable at high temperatures and kept the fiber morphology and thermodynamics in a stable state.

Carbonation: In the range of 1000-2000 degrees, the non-carbon elements in PAN are removed, and finally the carbon fiber with more than 90% carbon content and disordered graphite structure is produced.

Graphitization: Carbonized materials with amorphous and disordered layers are transformed into three-dimensional graphitized structures in the range of 2000-3000 degrees, which is the main technical measure to improve the modulus of carbon fibers.

The PAN precursor produced by the precursor production process is wet-hot pre-drafted on the wire feeder frame, then sent to the pre-oxidation furnace by the drawing mechanism in turn, and the pre-oxidized fibers (pre-oxidized fibers) are prepared after several pre-oxidation furnaces with different gradient temperature fields. The final product is treated by surface treatment, sizing and drying. The whole process of continuous wire traveling, accurate control, any one of the process problems will affect the stability of production and the final quality of carbon fiber products. Carbon fiber production process is a multi-disciplinary and multi-technology integration with long process, many key points and high production barriers.

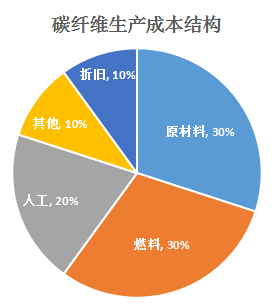

Carbon fiber price analysis

According to the production cost of carbon fiber, raw materials account for about 30%, fuel accounts for about 30%, labor accounts for about 20%, Depreciation accounts for about 10%, of which the supply of raw materials and fuel is stable and the price is transparent.

Overall, the average price of China's carbon fiber is 13-14.5 US dollars (90-100 yuan). Whether it is a large tow, or a standard modulus of 12K, 24K tow, in addition to Toray, other manufacturers into China prices are basically between 12-16 U.S. dollars, the Chinese market "quality, hundreds of dollars; inferior, hundreds of dollars" is an indisputable reality.

According to the current situation, a major breakthrough in the carbon fiber industry is about $10 a kilogram (or even lower) of carbon fiber prices, and can be profitable.

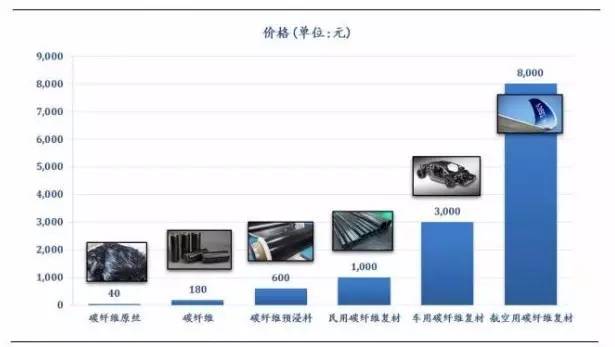

The added value of carbon fiber products with different uses varies greatly.

In the overall carbon fiber industry chain, the prices of products at different stages have increased substantially. The price of the same kind of precursor is about 40 yuan / kg, the carbon fiber is about 180 yuan / kg, the prepreg is about 600 yuan / kg, the civil composite is about 1,000 yuan / kg, the automobile composite is about 3,000 yuan / kg, and the aviation composite is about 8,000 yuan / kg. Jin, each level of deep processing has a substantial increase.

Analysis of carbon fiber giants abroad

1, Dongli, Japan (Toray)

Company profile: Dongli is the world's largest manufacturer of carbon fibers. Because of its lightweight, strong and hard advantages, Toray carbon fiber has a very wide range of applications in sports, leisure, general industrial applications and aviation fields.

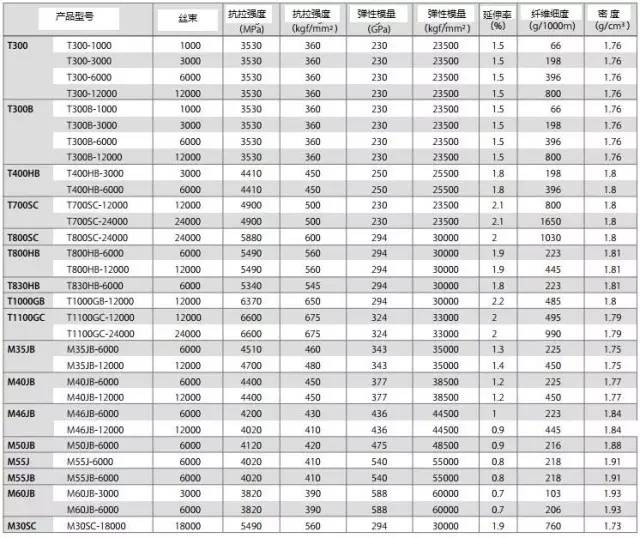

Major Products: Toray's products have two series, one is T series, representing high strength, the other is M series, representing high modulus. T series have T300, T400, T700, T800, T1000, etc. M series of carbon fiber main high modulus, product series have M30, M46, M50, M55;

Applications: It is widely used in aviation, construction and infrastructure, automotive parts, sports, leisure, and other fields.

2. Toho Tenax

Company Profile: Tohobang is one of the three largest carbon fiber producers in Japan and the world's second largest carbon fiber supplier, PAN carbon fiber.

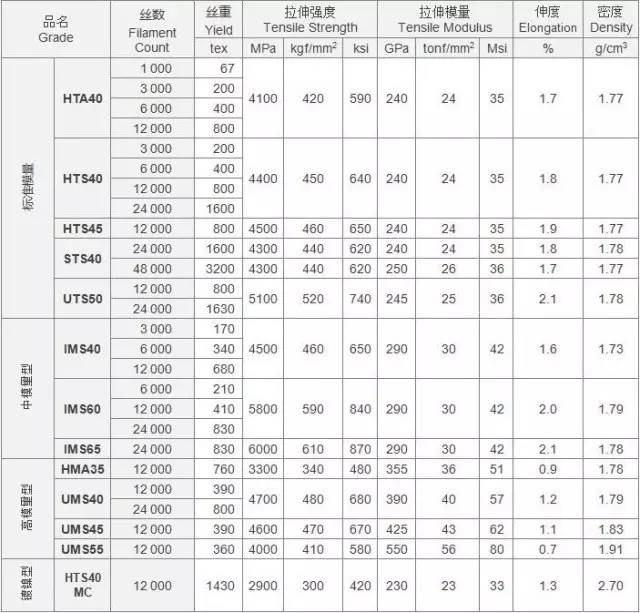

Main Products: Generally speaking, Dongbang carbon fiber can be divided into high-strength type: HTA40, HTS40; ultra-high-strength carbon fiber: UTS50; medium modulus and high-strength carbon fiber: IMS40, IMS60; high modulus carbon fiber: HMA35; Dongbang ultra-high modulus carbon fiber: UMS40, UMS45, UMS55.

Applications: automobile, aerospace, wind power generation, chemical equipment, medical equipment, sports goods and other fields.

3, MITSUBISHI Mitsubishi (Rayon)

Company profile: MITSUBISHI rayon is also called MITSUBISHI Liyang, belonging to MITSUBISHI chemical group. MITSUBISHI Liyang is a Japanese textile company, which mainly produces chemicals, plastics and fibers. MITSUBISHI Liyang is Japan's largest acrylic fiber producer.

Main Products: Mitsubishi Liyang Group also has PAN-based carbon fiber and pitch-based carbon fiber, as well as carbon fiber as the basic material for the production of intermediate materials and molding products. The products are divided into three series: high strength, medium modulus high strength and high modulus. Among them, the high-strength series are TR30, TR50, TR50D, TRH50, TRH60, TEW40; medium-modulus high-strength carbon fiber is MR60H; high-modulus carbon fiber is MS40, HR40, HS40.

Applications: automotive, aerospace, wind power, sporting goods and other fields.

4. Hirsch

Company Profile: Hershey has 40 years of carbon fiber manufacturing experience, a large number of aerospace data, and has many manufacturing plants in the United States and Europe. Hertz is a leader in medium modulus carbon fiber technology (small tows), capable of producing and supplying polyacrylonitrile (PAN) on its own and focusing on the development of precursors and carbon fibers.

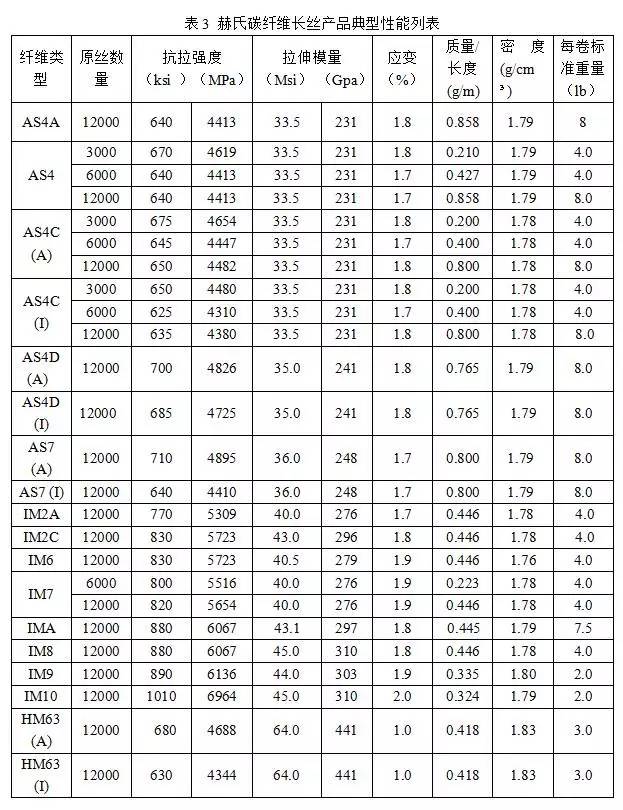

Main Products: Hertz carbon fiber in the United States is mainly divided into three series, high-strength, high modulus, medium-strength. The high-strength series have AS4 and AS7. IM is medium modulus high strength carbon fiber, IM2, IM6, IM7, IM8, IM9; high modulus carbon fiber HM63.

Applications: It can be used in the world's advanced products and fields, including: Airbus A350XWB, JSF, F18 E/F, A380, European Typhoon fighter, Global Express, A400M, V22 Osprey, Boeing 787, GEnx engine, etc. American Aviation Military carbon fiber mainly uses HEXCEL company's IM products, mainly IM7 (12K).

5, SGL, Germany

SGL Group-The Carbon Company, headquartered in Wiesbaden, Germany, is one of the world's leading manufacturers of carbon-graphite materials and related products. It has a complete business chain ranging from carbon-graphite products to carbon fiber and composite materials, and is currently the top five carbon fiber suppliers in the world.

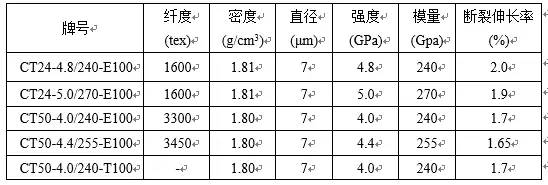

Main Products: SGL's carbon fiber products mainly include PANOX < oxidized fiber, SIGRAFIL < continuous carbon fiber, SIGRAFIL < short-cut carbon fiber and RECAFIL < regenerated carbon fiber. Its continuous carbon fiber products are acrylonitrile based (PAN) 24K+ carbon fiber products, and their typical properties are as follows.

Applications: Sustainable development solutions tailored to the general trends in transportation power and energy, covering the entire value chain from raw materials to finished products, products mainly used in automotive, wind and aerospace industries.

6, Belgian group

Company and Product Profile: Solvay S.A. is a multinational chemical group headquartered in Brussels, Belgium. It was founded in 1863 by the Belgian chemist Ernest Solvey.

The Belgian chemical giant acquired the US carbon fiber company CYTEC in 2015, with the US as its base to enter the carbon fiber market. On August 24, 2016, Solway officially opened a new carbon fiber production line in South Carolina, the United States, which will double the company's carbon fiber capacity, mainly for lightweight composite applications in aerospace. The expansion of the production line includes a full range of facilities for converting acrylonitrile monomers into standard modulus carbon fibers. This type of fiber is mainly used to manufacture composite prepreg for commercial or military aircraft parts. The new production line has won Boeing's secondary structural parts production qualifications, such as engine compartments, wing flap and interior accessories.

7. Korea's star company

Company Profile: The independent development of carbon fiber materials by Korea Xiaoxing Group in 2010 has aroused strong concern in the industry. In 2011, we established a semi commercial commercial production line of carbon fiber in South Korea. The carbon fiber production capacity was 500 tons / year. Xiaoxing Group invested more than 1.4 billion yuan to build a state-wide carbon fiber plant with an annual output of more than 2,000 tons. The plant was officially put into operation in April 2013, and plans to invest more than 7 billion yuan to establish a state-wide science and technology park for cutting-edge environmental protection materials. It is expected to be completed and put into operation by the end of 2020.

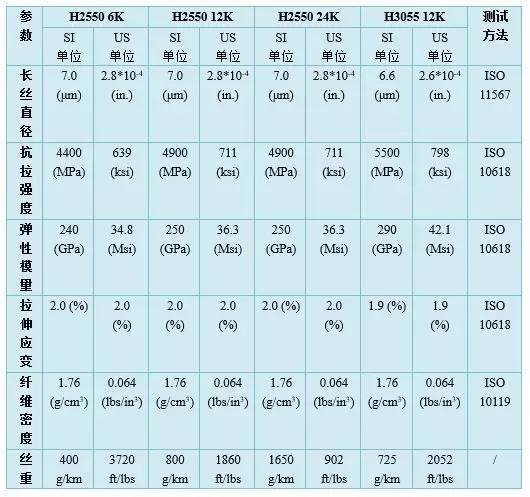

Main Products: There are only two types of high-strength products, including H2550 carbon fiber tensile strength of 4900 MPa, modulus of 240GPa, equivalent to T700 carbon fiber. The tensile strength of H3055 carbon fiber is 5500 MPa, and the modulus is 290GPa, which is equivalent to Dongli T800.

Applications: 70% of the world's carbon fiber core grade products are used in various industries, sports, leisure, aviation and other uses.

8, Al-aqsa (Aksa Akrilik Kimyasanayii)

Company Profile: Aksa Turkey was founded in 1968 and is the world's largest acrylonitrile fiber producer. In 2012, Aksa established a joint venture with Dow Aksa to form a large-scale, full-service carbon fiber supplier consisting of Turkish and American bases.

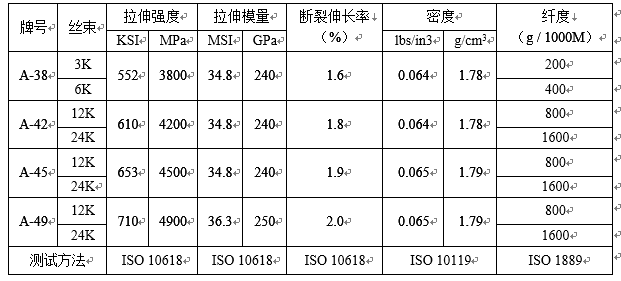

Main products: there are only 4 models, all of which are high strength carbon fibers. They are A38, A42, A45 and A49.

Applications: Mainly used in defense and commercial aerospace, in addition to infrastructure, ships, wind power generation and transport sectors.

People must read materials and materials, and understand the carbon fiber giants abroad.